|

COMMON QUESTIONS | ||||||||||

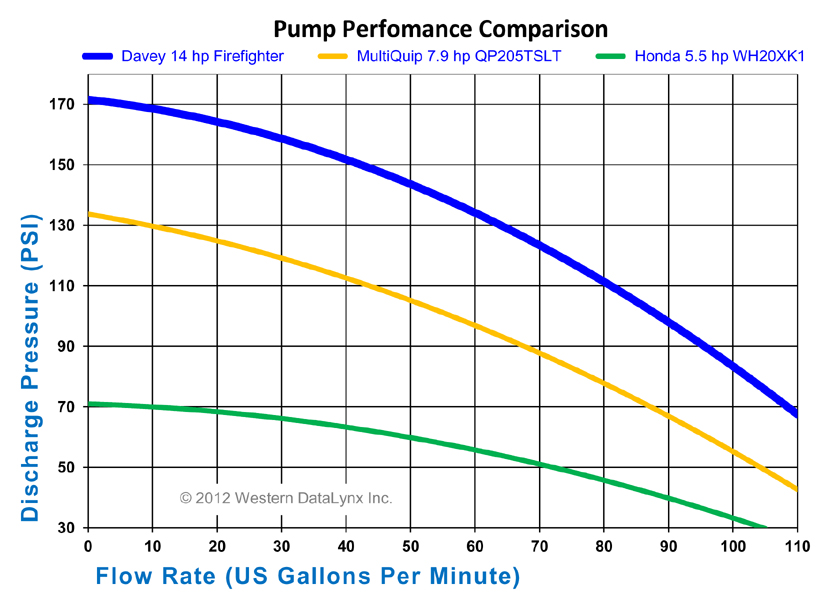

Which Home Firefighting® products are right for me ? Ultimately, only you can decide what equipment is best suited for your application. However to better assist you, we offer the following information and suggestions... Home Firefighting® equipment is the same equipment used by fire departments throughout the United States and worldwide. After extensive testing, we have selected to include as part of our Home Firefighting® product line those products which best provide homeowners with the added ability to pre-treat their their home/property and, if needed, fight a fire directly, while balancing price with performance. Our #1 suggestion when choosing a fire protection system is "ASK TO SEE A PUMP PERFORMANCE CURVE". We provide pump performance curves on all our pumps. A pump curve clearly shows how your pump will perform under actual firefighting conditions (See our pump narrative below).

When choosing your equipment, some questions to ask yourself are:

|

||||||||||

|

What makes our pumps better than other pumps ?

Flow is the volume of water leaving the pump over a given period of time and is usually measured in GPM (Gallons Per Minute). Don't be fooled by pumps with high GPH values (Gallons Per Hour) as you must divide that number by 60 to get actual GPM. Flow is important to know and control as it determines how fast you will use up your water supply. Pressure is the force at which the water leaves the pump in PSI (Pounds per Square Inch). For each pound of pressure, water can be raised 2.31 ft in a vertical pipe. Pressure is important as it controls how far the water can be pushed, both vertically and horizontally. With any pump, as Flow increases, Pressure decreases. Therefore, in order to properly evaluate a pumps performance for firefighting you need to know its Pressure rating at the rates of Flow you will be using when firefighting. Most pumps advertise their maximum PSI and maximum GPM. This can be deceiving since maximum PSI is achieved at zero GPM ("no-flow" or "static" conditions), while the maximum GPM is achieved at minimum PSI (close to zero pressure). Remember, what really matters is how many PSI the pump can produce at your GPM requirement! To determine the suitability of any pump look at it's pump curve (see our Firefighter® pump curves in the chart below). By following the curve to a specific flow rate you will be able to determine the pumps output pressure at that flow rate. Common firefighting equipment flow rates are 15-30 GPM for 1" hose and 30-60 GPM for 1.5" hose. So logically, you want to a pump that can produce the greatest Pressure at these Flow rates, to provide you with the greatest possible reach. FACT: While larger municipal fire engine mounted pumps can deliver from 90-300 GPM, those flow rates are unnecessary for homeowners and usually end up wasting a large amount of water. They also make the hose much harder to handle & control. Our Home Firefighting® Fire Pump offers greater Pressure than other pumps at these typical firefighting Flow rates. The pump heads used on our pumps have been proven effective through years of use in the Australian Outback and are currently being used in homes & ranches throughout the U.S. as well as by government and private forestry firefighting vehicles worldwide. |

||||||||||

|

What type of fire hose should I use? While some people may try to sell you double jacketed fire hose, there is no reason for the average homeowner to use it. Today's single jacket forestry hoses are lightweight extremely durable, kink resistant and can easily provide the flows needed to operate most fire equipment including foam and gel eduction systems. THESE ARE NOT THROW AWAY HOSES ! Our Home Firefighting® fire hose is manufactured for us by Key Hose (The largest manufacturer of fire hose in the US.) to NFPA, USDA and/or UL/ULC standards using state-of-the-art weaving processes to produce a rugged and durable hose product to meet the needs of firefighters! Our added coatings make them as durable as many heavier rubber lined and double jacket hoses that weigh twice as much. |

||||||||||

|

What size fire hose should I use ?

1" hose provides the best compromise between volume and manageability. 1" hose can deliver enough flow for most applications and is much easier for the average person to hold and move, especially for a long period of time. After all, what good is a fire hose if you can't handle it? FACT: While 1.5" hose is a primary hose for municipal fire departments, Forestry trucks often use 1" line for fighting fires since it is more maneuverable under extreme wildfire conditions. Also, if you look carefully at scenes of municipal firefighters in action you will see there are usually 2-3 firefighters manning each 1.5" line due to the weight of the hose and backpressure from the nozzle. Our 9hp Home Firefighting® Fire Pumps can easily drive two 1" lines simultaneously, providing greater simultaneous coverage than a single 1.5" line. Where long hose lays are required, a 1.5" hose can provide reduced friction loss before a transition to 1" hose for end of line manueverability. 3/4" hose is effective for mop-up and smaller maintenance jobs like using a foam kit to paint a house with foam or create a firebreak in grasslands around your home. It can be handled by pretty much anyone with ease. Don't be fooled by it's size though, this is not just another garden hose! It is designed to operate at pressures far above those produced by your normal faucet. Our consumer research with both firefighters and non-firefighters has shown an overwhelming preference for the maneuverability of a 1" fire hose by the average person. However, since everyone has a preference, we offer our systems with either 1" or 1.5" hose. In addition 2.5", 2", 1.5" and 3/4" hoses and adaptors can be ordered separately. |

||||||||||

|

How much hose should

I have on hand ? In some instances you might want to have multiple lines running so two or more people can protect different parts of the house simultaneously and you aren't constantly dragging the hose back and forth. If that is the case, remember to order an extra nozzle and valve for each hose. Friction loss is an important factor to consider when running long lengths of hose. As flow increases through a hose or pipe, so does friction loss (a decrease in pressure). When flowing 30gpm, a 1" fire hose will loose 15 PSI through a 50' length of hose. This is rather insignificant when using our high pressure (150+ psi pumps) but is of great significance if using a cheaper "trash" pump based system. So if you are need long hose runs we recommend using 1.5" for the hose lay to reduce friction loss, reduced to 1" at the operating end for easy of use by the operator. |

||||||||||

|

What is CLASS-A foam and what is a foam kit?

While there are many ways of adding foam, we prefer using a post pump eductor along with an aspirating nozzle at the end of the hose. Our end-of-line foaming kits utilize a solid foam cartridge or 1.5 gallon jug which can be easily replaced and adds little weight to the end of the line. The built-in eductor mixes the foamant at a 1% solution, the standard solution for most Class A foam applications. FACT: Foam eduction kits are designed to operate at 100 PSI nozzle pressure AT THEIR RATED FLOW IN GPM. Note: At a 1% eduction rate, 1 gallon of CLASS-A foam will treat approximately 100 gallons of water and increase it's effectiveness 3-5 times while covering approximately 4000 square feet.

|